forsewing

Brand New JUKI LS 1342 Cylinder Bed Walking Foot Sewing Machine

Brand New JUKI LS 1342 Cylinder Bed Walking Foot Sewing Machine

Couldn't load pickup availability

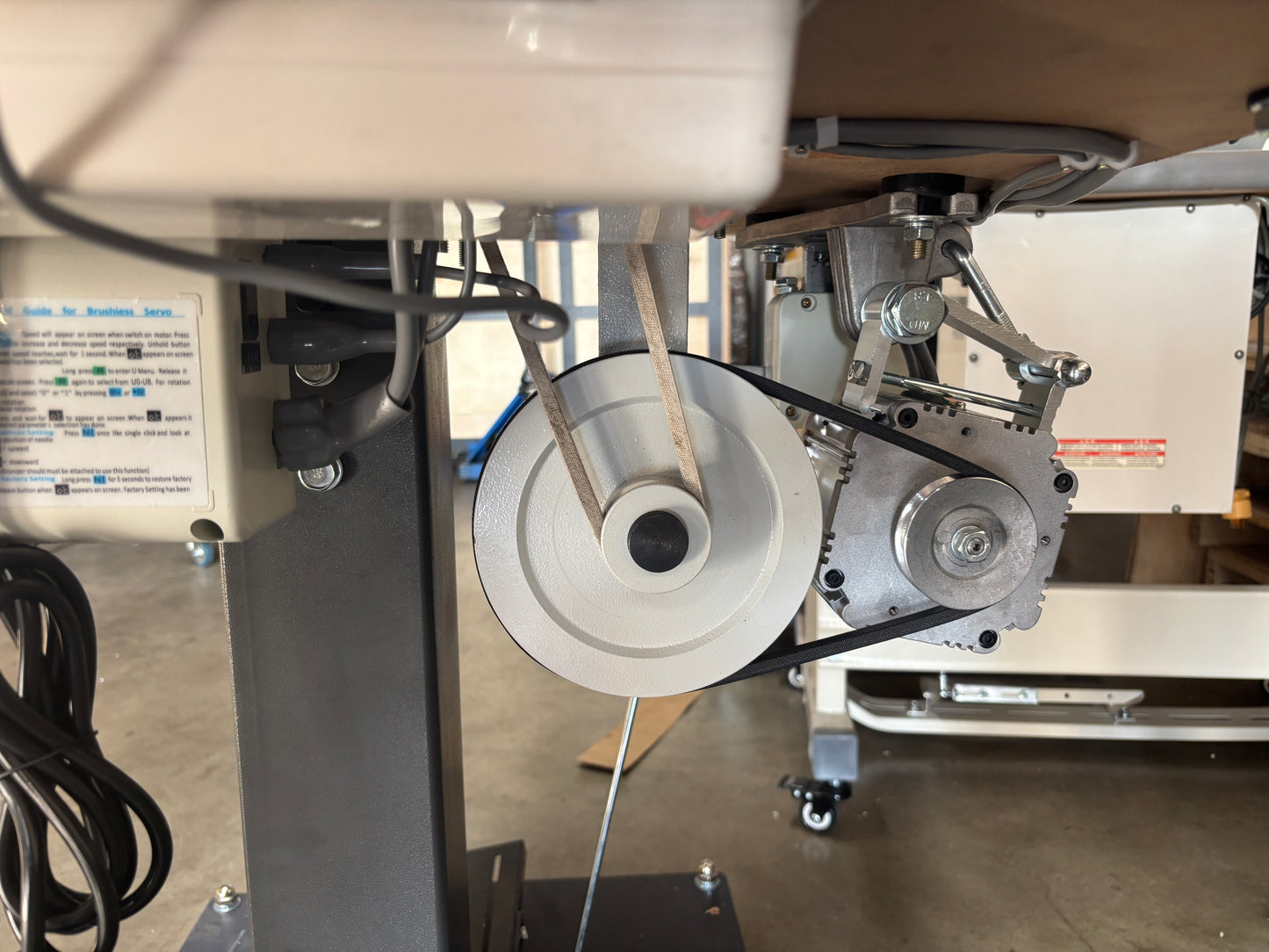

Brand new JUKI LS 1342 sewing machine head, made in Japan. Complete comes with pedestal stands which equipped with wheels make it easy to mover around. Brand new 750W servo motor with needle position.

- Suspended edge and roller guide;

- Double magnetic 30 LED lights with touch DIMMER.

- Presser foot with guide

- Wide zipper foot,

- Narrow zipper foot

- Narrow double-toe presser foot

- Binder attachment

- expand board (option)

LS-1342 Series

1-Needle, Unison Feed, Lockstitch, Machine with vertical-axis large hook

The LS-1342 are machines that have a more powerful feed and better responsiveness to thick-thread than standard machines.

LA-1342 is a compound feed machine with a large vertical-axis hook that makes the throat plate on the tip of the cylinder smallest to the utmost limit. Gauges for small articles are equipped as standard, therefore the machine is good at handling small articles and ideal for sewing articles with narrow gussets such as wallets and small bags.

Sewing capabilities and feed performance that respond to a broad range of uses in the sewing of heavy materials

With its larger needle bar stroke, a larger lift of the presser foot, and newly adopted double-tension mechanism, the machine sews beautifully with thick threads (low count thread) and at higher thread tensions. This allows the machine to sew a broad range of heavy materials.

Rectangular feed

Compared with the elliptical feed, the rectangular feed helps reduce gathered stitches.

Alternating vertical movement mechanism

The ratio of alternate vertical movement remains unchanged even when the material thickness changes.

Excellent for the sewing of sharp curves

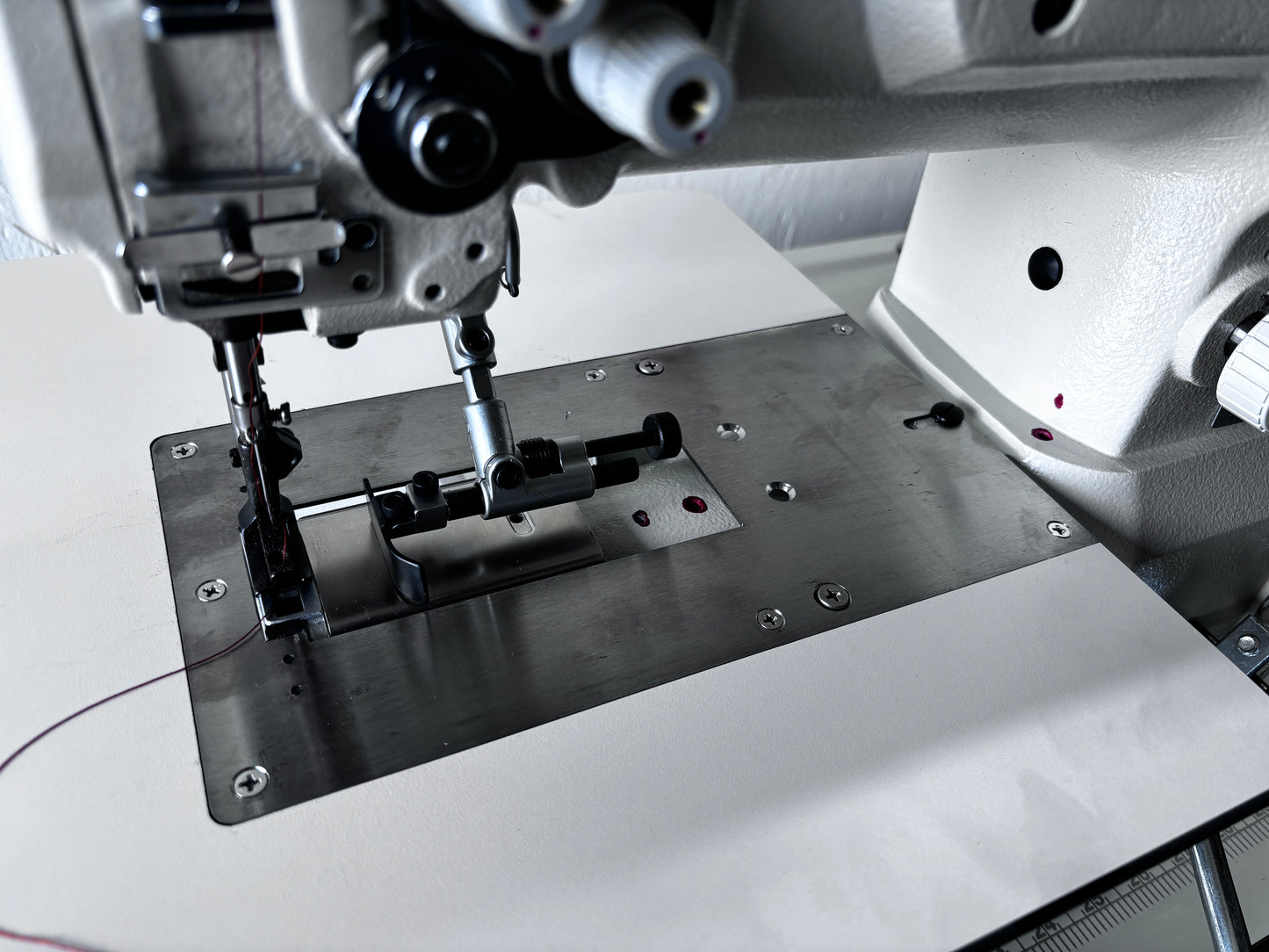

The slimmed-down throat plate easily responds to the sewing of small tubular articles with diameters as small as φ40mm. This enhances the machine's ability to smoothly sew not only bags and shoes but also small articles such as wallets.

Gauge for small articles are provided as standard

The throat plate and feed dog are provided with a gauge that offers an excellent capability for the sewing of sharp curves. These gauges are especially useful for the sewing of curves of bags and leather cases.

The vertical stroke of the walking foot and presser foot can be easily set and changed

The vertical stroke of the presser foot and walking foot (amount of alternating vertical movement) can be easily changed with the large dial mounted on the top of the machine head. The sewing speed is automatically regulated based on the vertical stroke setting. This ensures ideal sewing conditions at all times.

A helpful reverse feed function is provided as standard

With just a light press on the reverse feed handle, reverse feed stitching is actuated.

Excellent operability and maintainability

The underside of the top end of the cylinder-bed is provided with an easy-to-remove cover. This promises easy cleaning of thread wastes. The stitch length can be easily selected by the stitch dial. The machine's enhanced operability features include a clear view of the area around the needle, placement of the bobbin thread winder on the front face of the machine arm, and a large handwheel (φ160mm). A knee-lifter mechanism is built in the bed. This reduces the pressure required to operate the knee-lifter and facilitates setup. The machine’s full-open-type top design makes adjusting works easier. The machine comes with a lubricating mechanism that uses a centralized oil wick. This substantially reduces the time and trouble required for oiling the machine. (The hook needs manual oiling with an oiler.) A walking foot mechanism is built into the machine arm to prevent oil from scattering.

The area around the needle entry is designed to be easily observed

Since the needle thread-tension-release solenoid is fitted on the rear face of the machine head, the area around the needle entry is easily viewable. This substantially improves the operability of the machine.

Share